ARME

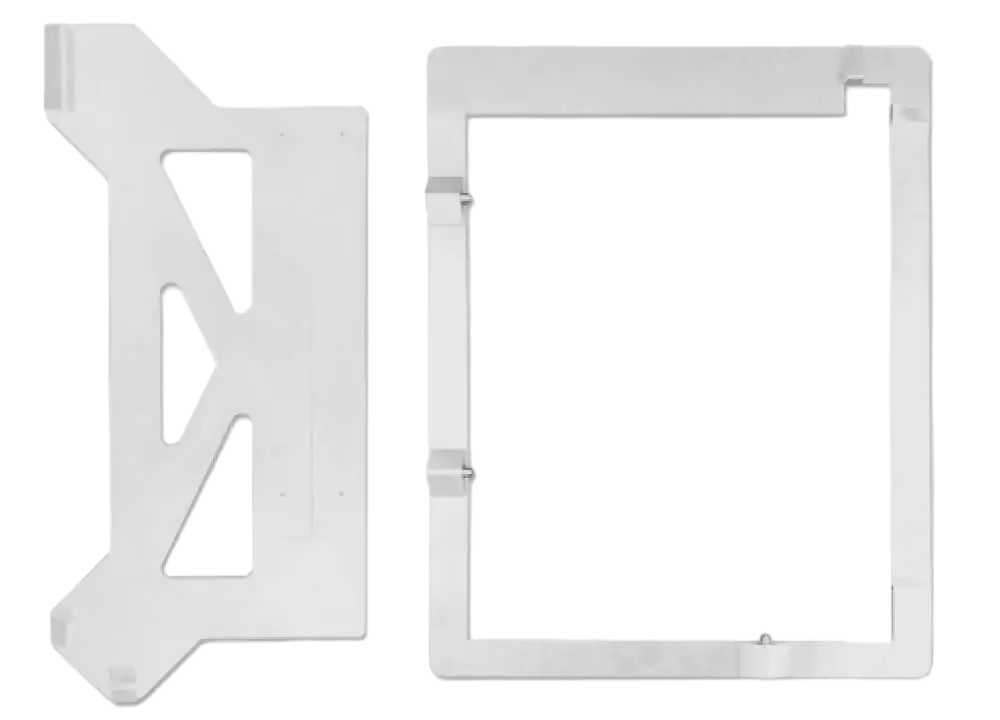

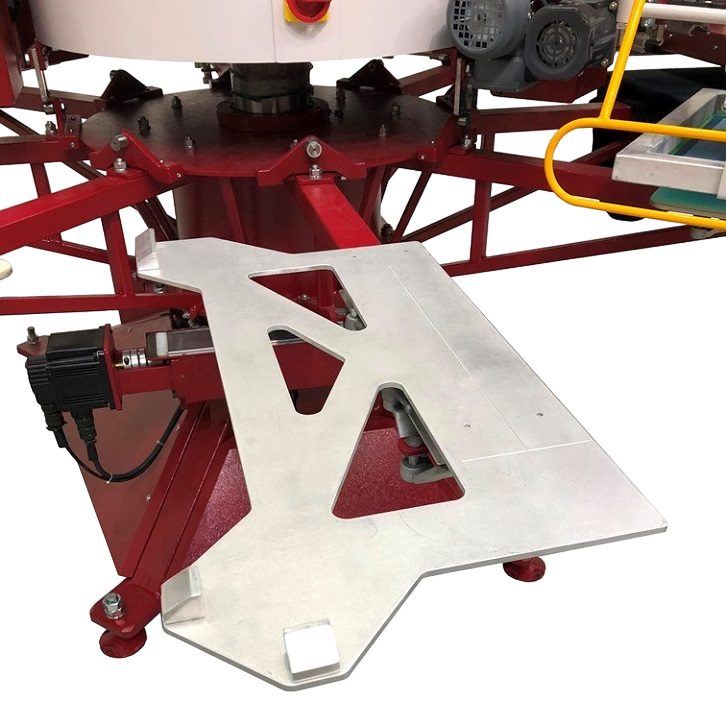

The ARME (Anatol Registration Made Easy) system is a user-friendly screen printing registration tool designed to save time and improve accuracy during setup. Compatible with all Anatol manual and automatic presses, ARME ensures precise screen alignment for high-quality prints. The system includes a master frame, guide pallet, and other essential tools, making it an essential addition to any screen printing shop looking to reduce setup times and maintain consistent print quality.

Description

Standard features

Specifications

Support

Transform Your Setup with the ARME Screen Printing Registration System

The ARME (Anatol Registration Made Easy) system is here to revolutionize your screen printing setup. This innovative screen printing registration system offers a fast, accurate, and incredibly user-friendly solution for aligning screens on both your exposure unit and press. Designed with the busy screen printer in mind, the ARME system is all about saving time during setup without sacrificing the precision you need for high-quality prints.

How the ARME Registration System Simplifies Your Workflow

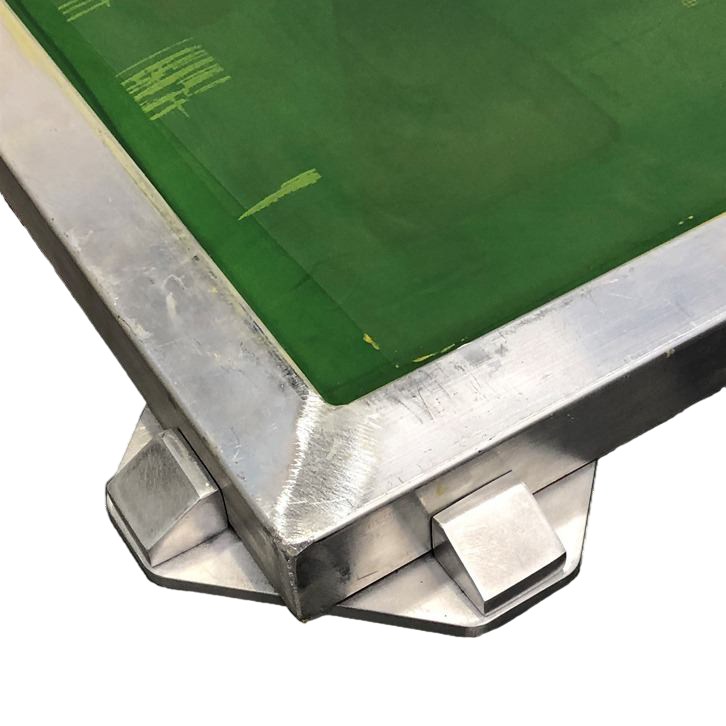

At its core, the ARME is all about simplicity and efficiency. It works by allowing you to align your film positives and screens directly on your light table or exposure unit using a specially designed master frame. Once you’ve got everything aligned just right, the screens are exposed and then easily transferred to your press. The included guide pallet is key here, replicating the registration points from the master frame, so when your screens hit the press, they’re already perfectly aligned. This setup virtually eliminates the need for tedious adjustments, cutting down your setup time dramatically.

A Versatile Solution for Every Shop

Whether you’re running an Anatol manual press or one of their automatic models, the ARME system is compatible across the board. It handles a variety of screen sizes—from 20”x24” to 26”x36”—making it a versatile addition to any print shop. The system is built to last, featuring durable materials like an aluminum guide pallet and a steel master frame, designed to withstand the demands of high-volume production environments.

Why Invest in the ARME Screen Printing Registration System?

In today’s fast-paced screen printing world, time is money. The ARME screen printing registration system is not just a tool—it’s an investment in efficiency and accuracy. Whether you’re dealing with large print runs or small jobs, the ARME system will help maintain perfect registration, leading to consistently top-notch prints. This is especially valuable when working with intricate designs where alignment is critical. By streamlining your setup process, this system reduces downtime and improves overall productivity.

Enhance Your Print Quality with Precision and Ease

The ARME screen printing registration system isn’t just about saving time; it’s about enhancing the quality of your work. With less time spent on alignment adjustments, you can focus more on the creative aspects of your printing process. This also allows you to dedicate more attention to the technical details. The result? Clean, precise prints that reflect the high standards of your shop. For any screen printing business looking to elevate its capabilities, the ARME system is essential equipment. It brings both reliability and innovation to your workflow.

FAQ

1. What screen sizes are compatible with the ARME system?

2. Can the ARME system be used with all Anatol presses?

3. How does the ARME system improve registration accuracy?

4. Is the ARME system easy to use for beginners?

5. Does the ARME system reduce setup times?

6. What materials are used in the construction of the ARME system?

7. Can the ARME system handle multiple screens at once?

8. How does the ARME system benefit my print shop?