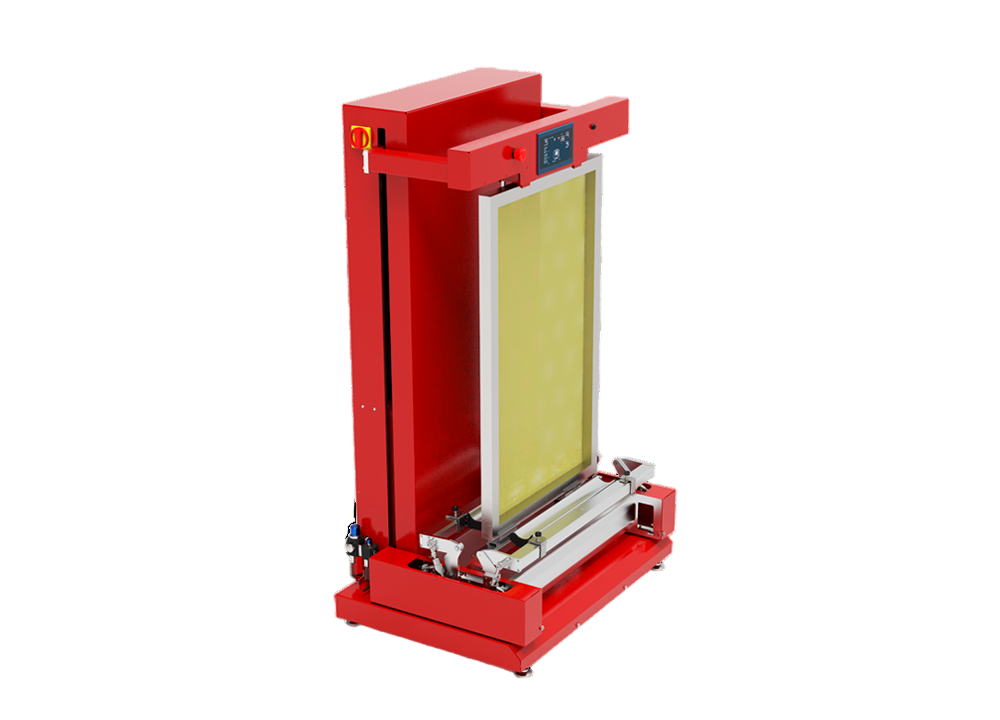

Quick-Kote Mini

The Quik-Kote Mini Automatic Emulsion Coating Machine is designed for small screen printing shops looking to improve their emulsion application process. This compact coater handles screen frames from 18”x19” to 30”x45”, applying a consistent, even coat of emulsion to both sides simultaneously. Equipped with an easy-to-use touchscreen, it allows you to save up to 15 different programs for quick setup. With servo motor-driven scoop coaters and adjustable screen locks, the Quik-Kote Mini ensures high-quality results every time.

Description

Standard features

Specifications

Support

Streamline Your Workflow with the Mini Automatic Emulsion Coating Machine

The Quik-Kote Mini Automatic Emulsion Coating Machine is a game-changer for screen printing shops, especially for those looking to enhance their emulsion application process. This mini emulsion coater is designed for efficiency and precision, making it an essential tool for small to mid-sized operations. Capable of handling screen frames ranging from 18”x19” to 30”x45”, the Quik-Kote Mini is ideal for space-limited shops. It delivers top performance where space is limited, but performance is non-negotiable.

Precise and Efficient Coating

One of the most significant advantages of the mini emulsion coater is its ability to coat both sides of the screen simultaneously. This feature drastically reduces screen preparation time while ensuring a uniform and consistent layer of emulsion. The machine’s servo motor-driven scoop coaters apply the emulsion smoothly and evenly, eliminating common issues such as air bubbles or streaks. The adjustable screen locks are versatile, accommodating various frame sizes and thicknesses, ensuring a secure hold during the coating process and contributing to the machine’s consistent performance.

User-Friendly Controls

The Quik-Kote Mini is equipped with a 7’’ touchscreen control panel that is both intuitive and user-friendly. Operators can easily set up and control the automatic emulsion coater through this interface. Additionally, the machine allows saving and recalling up to 15 different coating programs. This feature is particularly beneficial for shops that frequently switch between different screen sizes or emulsion types, offering quick adjustments and consistent results every time.

Compact Design Quik-Kote Mini Automatic Emulsion Coating Machine for Small Shops

Constructed with durability in mind, the Quik-Kote Mini Emulsion Coater is made from high-quality materials designed to withstand the demands of daily use. Despite its robust performance, this compact emulsion coater has a space-saving design. It’s a perfect fit for shops with limited space. Its compact size doesn’t compromise its capabilities. It ensures that your screens are coated with precision. This leads to high-quality prints and a more efficient workflow.

Consistent and Professional Results

Whether you’re coating screens for plastisol, water-based, or specialty inks, the Quik-Kote Mini guarantees consistent results. It delivers professional quality with every use. This screen printing emulsion coater is an investment in quality and efficiency. It improves both the speed and accuracy of your screen preparation process.

The Quik-Kote Mini Emulsion Coater is not just a machine; it’s a vital component of your screen printing workflow, designed to deliver precise and reliable emulsion application every time. Whether you’re running a small operation or need a reliable secondary coater, this equipment from Anatol is your go-to solution.

FAQ

1. What is the maximum screen size that the Quik-Kote Mini can handle?

2. Can this machine coat both sides of the screen simultaneously?

3. Is the Quik-Kote Mini suitable for small screen printing shops?

4. How many coating programs can be saved on the Quik-Kote Mini?

5. What type of emulsion can be used with this machine?

6. Does the machine require manual operation?

7. How is the machine controlled?

8. Is the Quik-Kote Mini energy efficient?