A manual press is a vital tool for screen printing, bringing your creative visions to life with precision—when it’s properly maintained. Regular manual press maintenance keeps it dependable, preventing unexpected hiccups that can stall your workflow. For anyone using equipment from the manual presses category, these practical tips offer a roadmap to better performance and a longer lifespan, letting you focus on crafting quality prints without the stress of sudden repairs.

Start with Cleanliness: A Simple Habit with Big Impact

Overlooking cleanliness is a rookie mistake that can quietly undermine your press. Ink splatters, dust, and tiny debris don’t just mar your prints—they can also wear down components over time, leading to costly repairs. By weaving cleaning into your manual press maintenance habits, you’ll prevent manual press wear and keep your setup primed for action. It’s a small effort that delivers outsized rewards, especially for those who rely on their press daily.

- Focus on essentials: After each printing session, take a moment to clear ink off platens, frames, and any surfaces it might cling to—this stops buildup in its tracks.

- Use gentle methods: Grab a soft rag and a mild cleaner like isopropyl alcohol; steer clear of rough scrubbers or chemicals that could scratch or degrade metal parts.

- Make it regular: A quick wipe-down after use keeps things manageable, while a thorough scrub once a week tackles anything you might’ve missed.

Fine-Tune Components for Steady Results

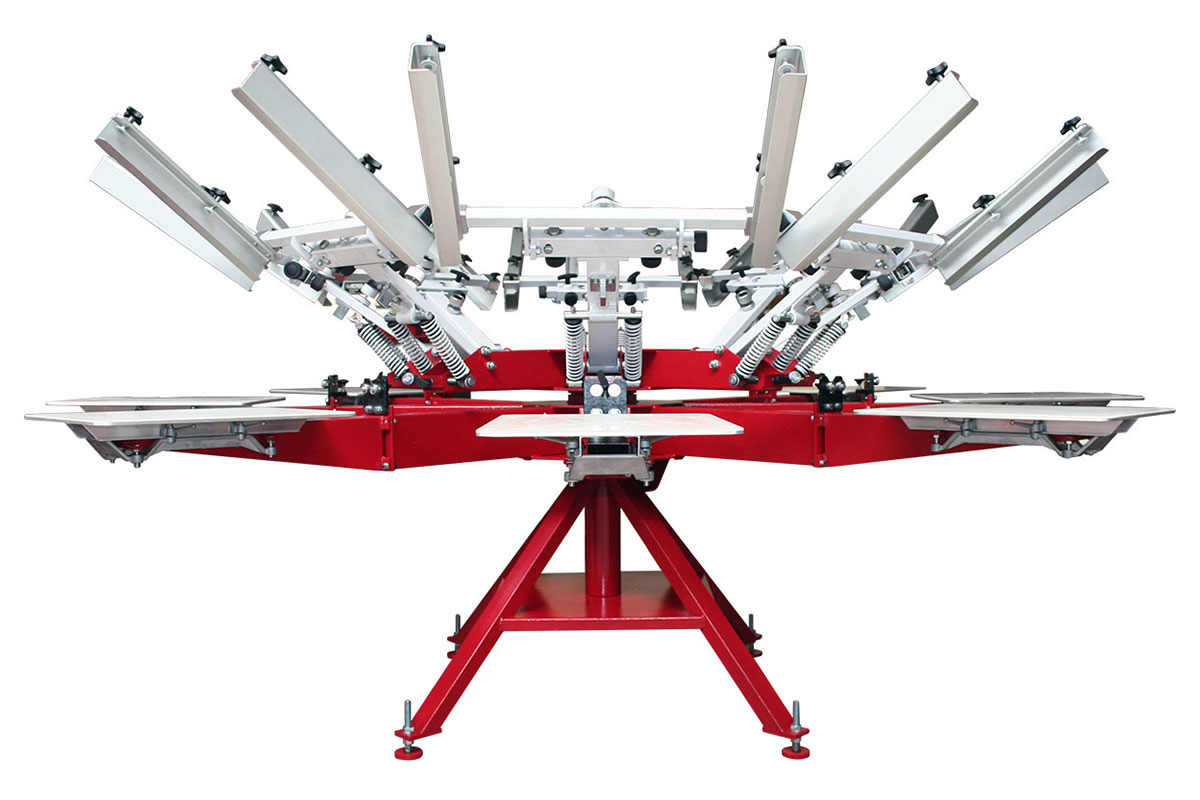

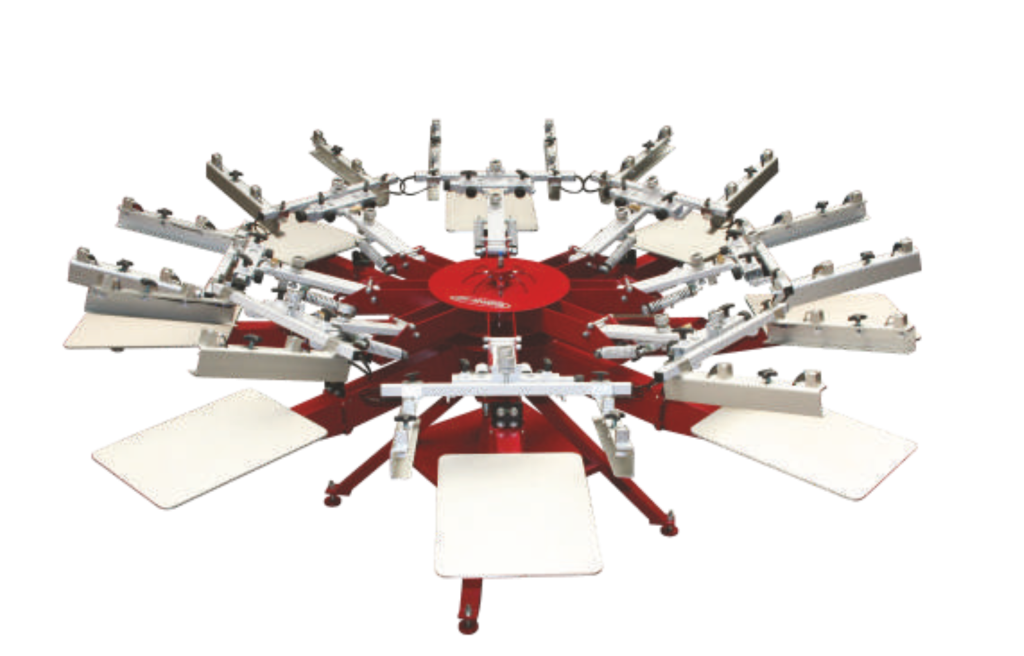

A press that’s even slightly off-kilter can turn a perfect design into a blurry mess. Loose screws or an unlevel platen might seem minor, but they add up, affecting precision and consistency. Learning how to maintain a manual press with periodic adjustments can improve manual press performance significantly. This is particularly true for durable options like thunder from the manual presses range, which thrive with a little attention to detail.

- Check alignment: Take a close look at the platen—use a level if needed—to ensure it’s perfectly even, guaranteeing uniform pressure across every print.

- Tighten carefully: Grab a wrench and gently secure any loose bolts or screws; overdoing it can strip threads, so a light touch is key.

- Lubricate joints: Every two or three months, dab a bit of light machine oil on hinges and pivot points to keep movements fluid and friction-free.

Guard Against Rust and Wear

Your press faces invisible threats like humidity and low-grade supplies that can erode its condition over time. Rust creeping onto metal surfaces or wear from abrasive inks can cut its lifespan short if you’re not proactive. Protecting it is a straightforward way to boost manual press longevity and prevent manual press wear, ensuring it remains a trusty tool for all your printing needs.

- Store wisely: Keep your press in a dry, well-ventilated spot—adding a dehumidifier can be a game-changer in damp environments like basements or coastal areas.

- Stick to quality: Invest in reputable inks that won’t corrode or leave harsh residues; cheap alternatives might save a buck now but cost you later.

- Go easy on cleaners: Opt for mild solutions over aggressive ones—harsh chemicals can strip protective coatings and invite rust instead of preventing it.

Adjust Settings for Better Prints

The difference between a good print and a great one often lies in how well you’ve dialed in your press. Pressure that’s too high or a worn-out screen can throw off your results, but a few tweaks can fix that. These essential tips for manual press care are all about helping you improve manual press performance. They’re especially handy for adaptable models like tornado from the manual presses category.

- Set pressure right: Adjust it based on your fabric—thicker materials need more force—and always run a test print to confirm it’s spot-on.

- Inspect screens: Check your meshes for stretching or tears; swapping them out when needed keeps your designs sharp and clean.

- Experiment a bit: Print a few samples to fine-tune settings before committing to a full run—it’s a small step that saves big headaches.

Address Issues Before They Worsen

Even the best presses can show signs of strain—think faint creaks or prints that don’t quite line up. Ignoring these early warnings can lead to bigger problems down the road, from misaligned parts to complete malfunctions. Mastering how to maintain a manual press with a proactive manual press maintenance approach keeps those issues manageable and your workflow intact.

- Listen closely: If you hear squeaking or grinding, a quick dab of lubricant on the offending joint can silence it before it worsens.

- Watch for flaws: Uneven or faded prints often mean alignment’s off—recalibrate the platen or arms to bring things back in line.

- Know your limits: For anything beyond simple fixes, like persistent jams or odd vibrations, a technician can step in to sort it out.

Dedicating a little time to your manual press’s care can transform it into a long-lasting partner for your printing projects. These steps not only ensure manual press longevity but also let you focus on what matters—crafting standout designs. If you’re ever curious about exploring models like tornado or thunder, the manual presses category is full of ideas worth checking out for your next creative venture.