Quick-Kote Automatic

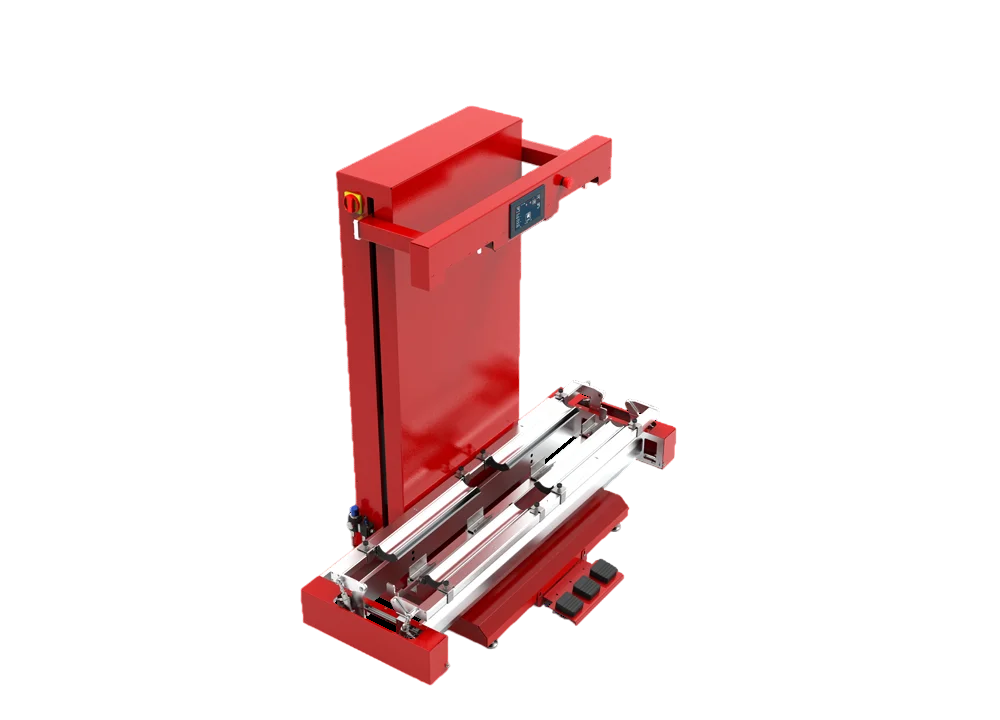

The Quik-Kote Automatic Emulsion Coating Machine is designed for screen printing shops that demand precision and efficiency. Capable of coating one or two screens simultaneously, this machine ensures consistent emulsion layers for improved print quality. Its servo motor-driven scoop coaters apply emulsion smoothly and evenly, reducing screen preparation time and enhancing overall production efficiency. The machine’s intuitive 7’’ touchscreen control panel allows operators to save up to 15 different coating programs, making it an essential tool for high-volume production environments.

Description

Standard features

Specifications

Support

Revolutionize Your Screen Preparation with the Quik-Kote Automatic Emulsion Coater

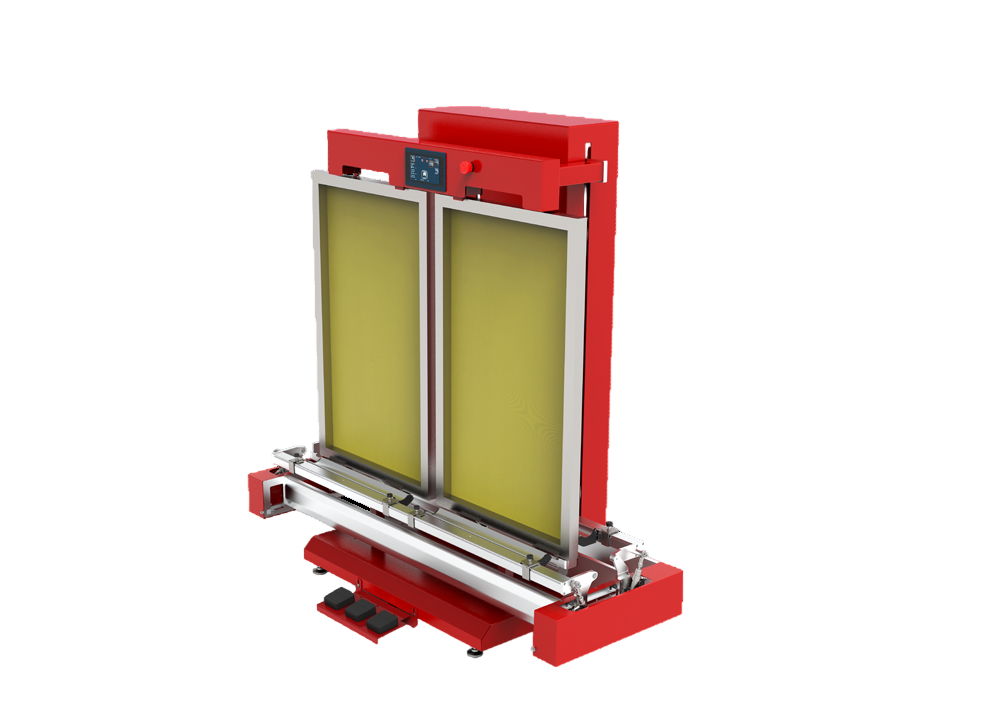

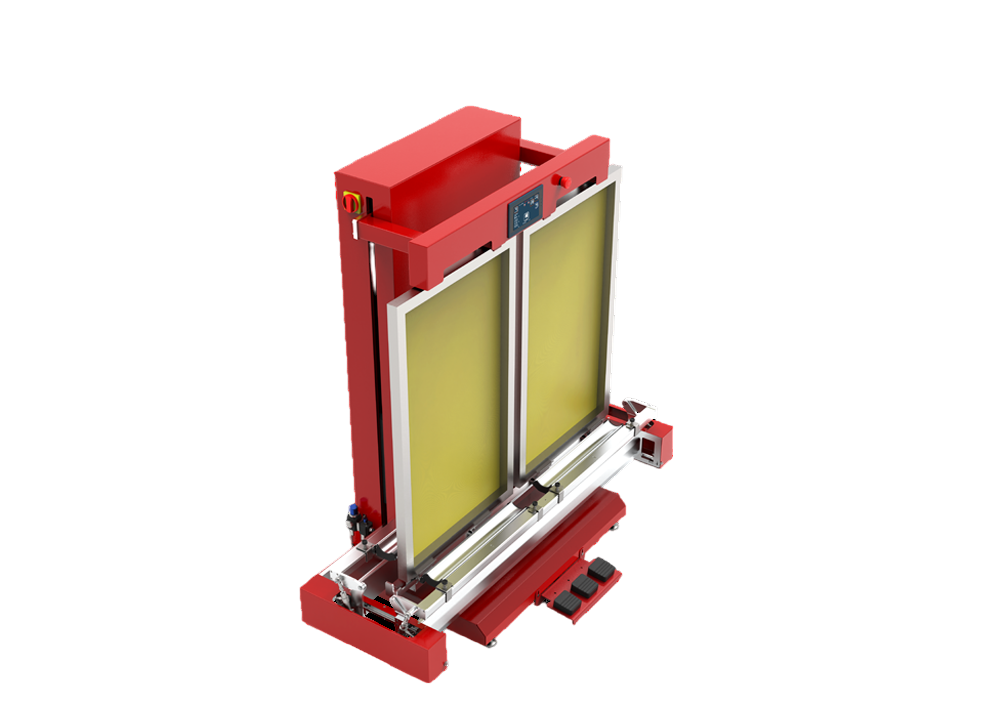

The Quik-Kote Automatic Emulsion Coater is a game-changer for screen printing shops looking to enhance their screen preparation process. Designed to coat one or two screens at a time, this advanced machine ensures that each screen receives a consistent and even layer of emulsion. This consistency is key to producing higher-quality prints and increasing efficiency in your shop.

High-Performance Features for High-Volume Production

Built with high-volume production in mind, the automatic emulsion coater features servo motor-driven scoop coaters. These coaters apply emulsion smoothly and uniformly, eliminating common issues such as air bubbles or uneven layers. This precision is critical for achieving high-resolution prints, especially when working with intricate designs or fine halftones. The machine’s aluminum scoop coaters are not only durable but also designed for easy cleaning, ensuring your equipment remains in top condition with minimal maintenance.

Easy-to-Use Controls for Seamless Operation

One of the standout features of the Quik-Kote is its user-friendly 7’’ touchscreen control panel. This intuitive interface allows operators to easily manage the entire coating process. You can save and recall up to 15 different programs, making it simple to switch between different screen sizes or emulsion types. The automatic screen coater also automatically detects when screens are loaded and provides an error message if they are improperly placed, ensuring a seamless operation every time.

Durable Construction and Space-Saving Design Quik-Kote Automatic Emulsion Coater Machine

With its robust construction, the Quik-Kote Automatic Emulsion Coater is built to withstand the demands of a busy screen printing shop. Its compact footprint also saves valuable space. Whether you’re coating screens for plastisol, water-based, or specialty inks, this machine is an essential tool for achieving consistent, professional results. Its durable design ensures longevity, making it a reliable addition to any screen printing operation.

A Must-Have for Professional Screen Printing Shops

The Quik-Kote Automatic Emulsion Coater is not just a machine. It’s an investment in the quality and efficiency of your screen printing process. With features that cater to high-volume production, this industrial emulsion coater is ideal for busy environments. It delivers precise, consistent coatings, making it perfect for both large and small shops. Its fast, reliable, and user-friendly design makes it a must-have for any professional screen printing setup.

FAQ

1. What is the maximum screen size the Quik-Kote can handle?

2. Can the Quik-Kote coat two screens simultaneously?

3. Is this machine suitable for high-volume production?

4. How does the machine ensure even coating?

5. What kind of control does the machine offer?

6. Is the Quik-Kote easy to maintain?

7. What type of emulsions can be used with the Quik-Kote?

8. Does the machine provide error notifications?