Rapid Wave

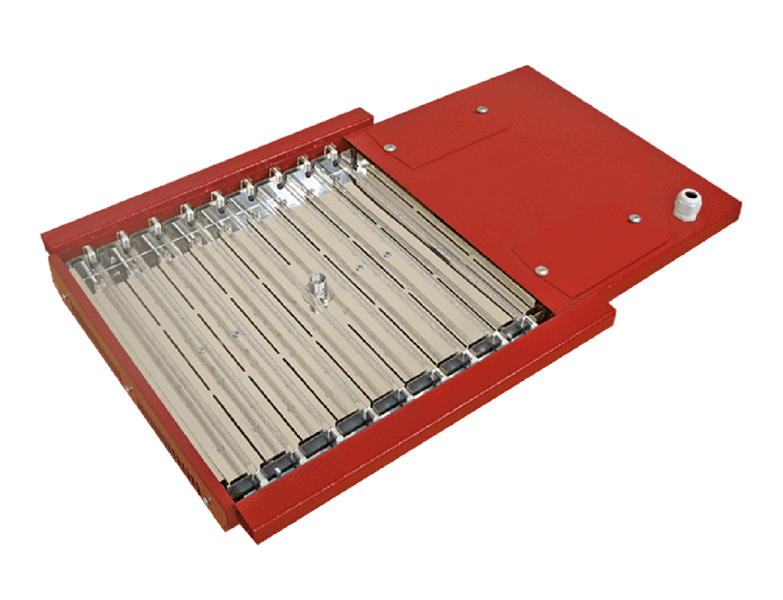

The Rapid Wave Flash Dryer is engineered for high-volume screen printing, offering quick and efficient flash curing. Equipped with ultra-fast quartz lamps and variable intensity controls, this dryer ensures precise heat application. With multiple curing zones, it adapts to various printing needs, making it ideal for large-scale operations. The Rapid Wave is available in five sizes, from 16” x 16” to 30” x 40”, and can be integrated with Anatol automatic presses or used with manual presses for maximum versatility.

Description

Standard features

Specifications

Support

Introduction to Rapid Wave Flash Dryer

The Rapid Wave Flash Dryer by Anatol is designed for screen printing shops that demand speed, precision, and efficiency in their flash curing processes. This advanced dryer uses medium wave quartz lamps that heat up quickly and cool down just as fast, minimizing energy consumption while maximizing production speed.

Zone Control for Customized Curing

The quartz lamps are arranged in zones, allowing you to activate specific areas of the dryer to match the size of the substrate, ensuring even and effective curing across the entire print. This zone control is critical for achieving uniform heat distribution and maintaining the quality of the print on various substrates.

Variable Intensity Control for Optimal Results

One of the standout features of the Rapid Wave is its variable intensity control, which lets you fine-tune the heat output to suit different ink types and materials. Whether you’re working with plastisol, water-based, or specialty inks, this dryer provides the flexibility you need to achieve consistent results every time.

Advanced Features for Enhanced Curing

The built-in temperature sensor enables you to program and maintain the optimal curing temperature. This reduces the risk of scorching or under-curing your prints. This precise temperature control is essential for maintaining high-quality standards in your screen printing outputs.

Versatility Across Applications

The Rapid Wave Flash Dryer is available in five models, with curing areas ranging from 16” x 16” to 30” x 40”. This variety makes it suitable for a wide range of screen printing applications. It can be easily integrated with Anatol automatic presses for seamless operation. Alternatively, it can be mounted on an adjustable floor stand for use with manual presses.

Energy Efficiency and Design

This versatility, combined with its energy-saving design, makes the Rapid Wave Flash Dryer a top choice. It’s particularly favored by high-volume screen printing shops. The energy-efficient quartz lamps and the ability to target specific areas for heating help reduce overall operational costs.

Conclusion: A Smart Investment for Screen Printers

Investing in the Rapid Wave Flash Dryer equips your shop with a top-tier flash cure system. This system enhances productivity without sacrificing quality. With its robust design and advanced curing capabilities, it stands as an essential component of modern screen printing operations. This ensures each project benefits from rapid and reliable flash drying

FAQ

1. What sizes are available for the Rapid Wave Flash Dryer?

2. How does the temperature sensor benefit my screen printing process?

3. Can the Rapid Wave Flash Dryer be used with manual presses?

4. What is the advantage of multiple curing zones?

5. How does the Rapid Wave Flash Dryer save energy?

6. Is the Rapid Wave Flash Dryer suitable for high-volume production?

7. What types of inks can be cured with the Rapid Wave Flash Dryer?

8. What are the electrical requirements for the Rapid Wave Flash Dryer?