Vector

The VECTOR Series by Anatol offers unmatched precision and efficiency for commercial t-shirt printing. This automatic screen printing machine blends electric and pneumatic technology to deliver consistent, high-quality results. Designed for versatility, it features various print sizes, making it ideal for businesses seeking reliable and cost-effective printing solutions.

Description

Standard features

Specifications

Support

The VECTOR Series: Automatic Screen Printing Machine

If you’re seeking a reliable and efficient solution for your commercial screen printing needs, look no further. The VECTOR Series by Anatol is the perfect choice. This automatic screen printer perfectly bridges the gap between traditional pneumatic-based presses and fully electric systems like the VOLT, offering the best of both worlds.

The VECTOR Series employs advanced electric technology combined with pneumatic features. These features include free wheel indexer locking/unlocking and up-and-down squeegee/flood bar movement. This unique combination is known as the SSE configuration—servo lift, servo indexing, and AC electric print heads. It ensures you achieve consistent and reliable prints every time.

Why Choose the VECTOR Series?

One of the standout features of the VECTOR is its low air consumption, which is the best in the industry. With 90% fewer pneumatic parts than other presses, the VECTOR reduces air usage, lowers maintenance needs, and cuts operating costs. This efficiency not only saves you money but also reduces the machine’s environmental impact, making it a smart choice for eco-conscious businesses.

Designed to be the most versatile automatic screen printing machine on the market, the VECTOR Series comes in more sizes than any other auto screen printing machine. It offers print areas ranging from 15″ x 16″ up to 20″ x 28″, and models that range from 4 to 18 colors. Whether you’re handling small or large orders, the VECTOR adapts to your needs—without compromise.

User-Friendly Interface and Flexibility

The VECTOR includes a user-friendly control interface that makes setup and operation a breeze. This commercial t-shirt screen printing machine allows you to store and recall job settings quickly, speeding up setup and ensuring consistent results. Designed to grow with your business, this small automatic screen printing machine offers the flexibility to handle changing demands with ease.

Built to Last

The VECTOR Series is engineered to last, with a robust frame and high-quality components that guarantee long-term performance. It’s an investment that will keep delivering top-quality prints for years. Whether you need an automatic silk screen press or a commercial screen printer, the VECTOR is built to meet your needs.

A Versatile Solution for All Your Printing Needs

The VECTOR Series isn’t just a t-shirt printing machine; it’s a complete solution for all your screen printing needs. Whether you’re printing shirts, promotional products or other items, the VECTOR delivers reliable, high-quality results. If you’re looking for an automatic screen printing machine for sale, the VECTOR Series offers great value with features that set it apart from the competition.

With the VECTOR, you’re not just getting a screen printer for shirts; you’re investing in a silk screen printing machine designed to handle all the demands of a busy print shop. For even the most complex t-shirt printing, this screen press machine offers the versatility and reliability you need to succeed.

Other automatic screen printing machines by Anatol Manufacturing Equipment Co:

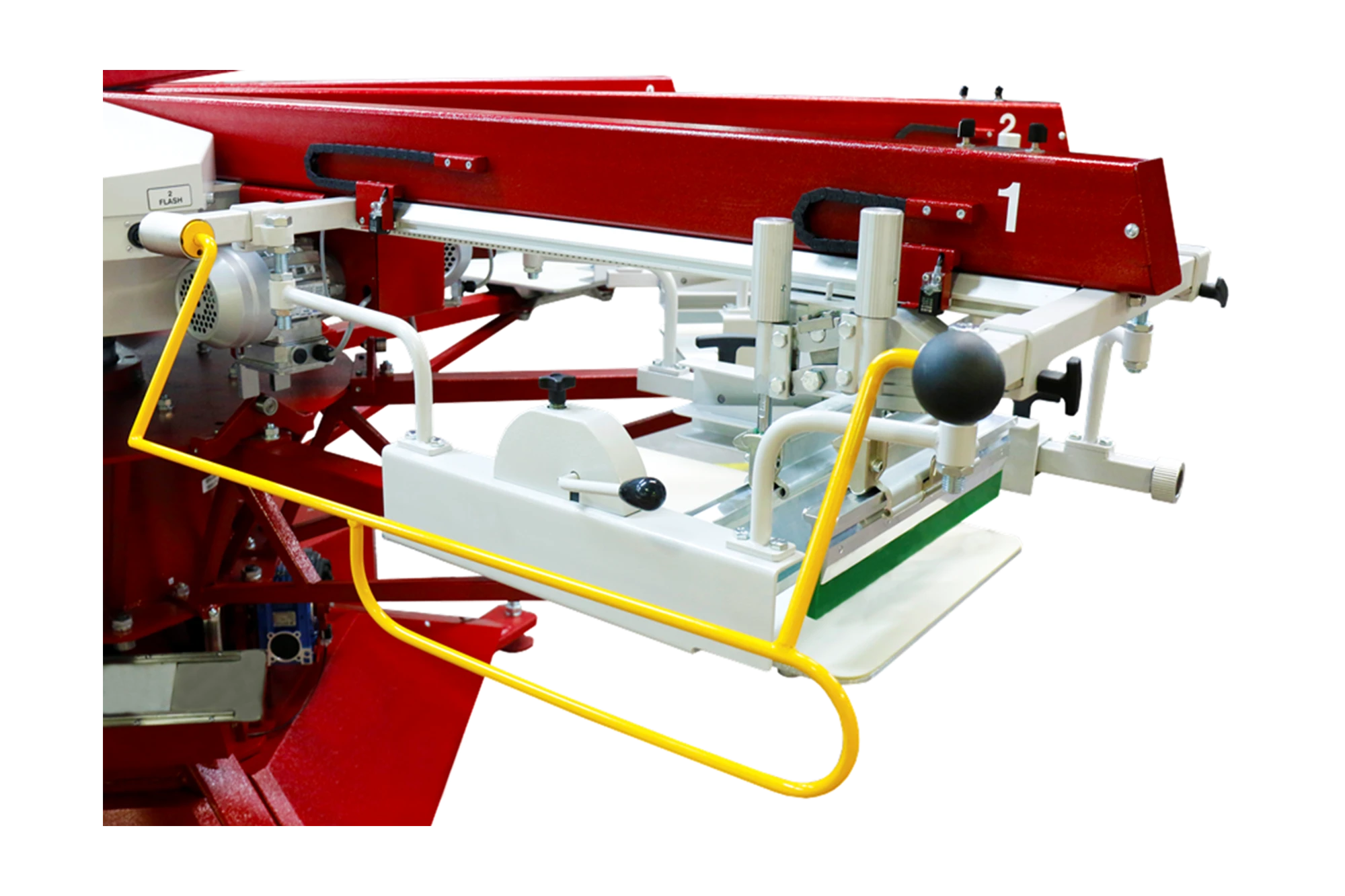

Print Heads

AC electric-driven print heads provide smooth operation, enhanced speed, and increased power for precise printing. The heads feature front and rear stroke adjustment, and the tool-less squeegee/flood bar locking mechanism allows for quick and easy changeover.

Registration

Control Interface

Powered by the Aries 2 OS, the VECTOR offers a 15” touchscreen interface with intuitive controls. One-touch access to all job settings and machine functions allows for fast and easy setup. The rotating boom arm ensures accessibility to each print head.

Functions

The machine’s control system offers easy setup mode, significantly reducing setup times. Its advanced features ensure consistent quality across various print jobs, with the ability to store and recall different job settings.

Heads Up Feature

On machines with an odd number of print heads, the VECTOR allows you to raise the last head to create dedicated loading and unloading stations. This feature enhances workflow efficiency, effectively giving you two machines in one.

Pallet System

The VECTOR’s slide-style pallets allow for precise adjustments in print location. The tool-free locking system and four-point pallet leveling ensure that each print is perfectly aligned and consistent, with standard 16”x22” low-profile rubber-coated pallets included.

Skip Shirt & Smash Button

Save time and resources with the skip shirt feature, which prevents the press from printing on empty pallets. The smash button halts printing instantly if a shirt is loaded improperly, ensuring fewer errors and less waste.

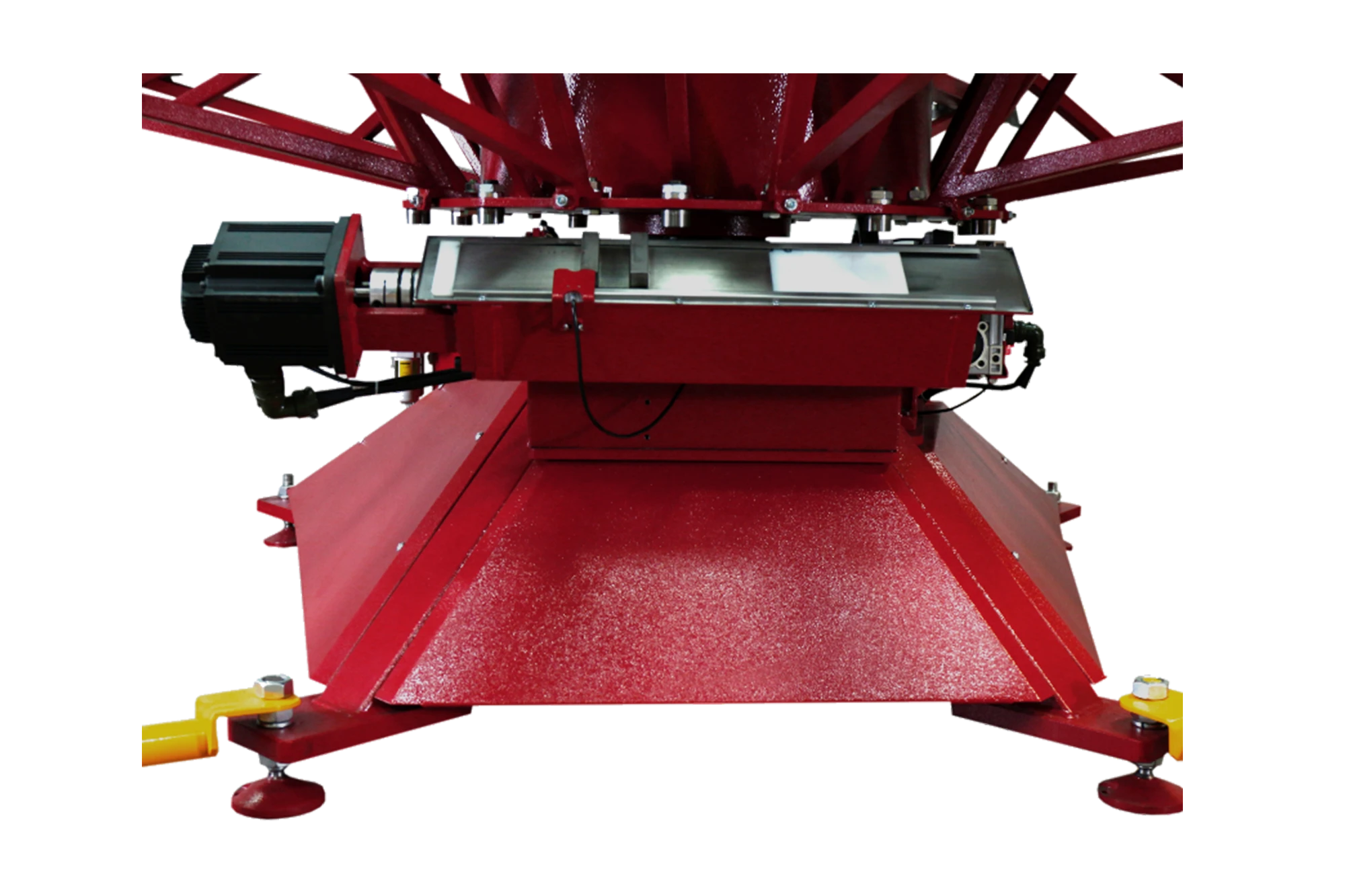

Indexing System

The VECTOR’s servo-driven indexer supports clockwise, counterclockwise, and half-indexing for smooth, quiet operation even at high speeds. The freewheel capabilities allow for manual carousel rotation when needed.

Options

The VECTOR offers a range of options, including a quick-release pallet system, foot pedal control for indexing, and quartz flash cure units. Custom sizes are available to fit through doorways as small as 28’’, making the machine versatile for different workspace requirements.

Safety System

Equipped with safety bars between each print head and at the load/unload stations, the VECTOR ensures safe operation during press setup and throughout the printing process, protecting operators from potential hazards.

Central Off-Contact

Digitally-controlled central off-contact with 38 settings up to 3/8’’ allows you to adjust the distance between the screen and substrate. This flexibility makes it easy to print on a wide variety of materials with different inks.

Laser Alignment System

The VECTOR includes a laser alignment system with four independently-adjustable red lasers, making it quick and easy to perfectly align garments on the pallets, reducing setup time and improving print accuracy.

Vector S

Vector M

Vector L

Vector XL

| Stations Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Press Diameter | Stationary Arm or Boom Touchscreen Support | Electrical Requirements | Air Requirements @ 90 PSI | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 06/04 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 9’4” | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min | 06/05 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 9’4” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min | 08/06 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 10’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min | 08/07 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 10’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min | 10/08 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 11’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min | 10/09 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 11’2″ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min | 12/10 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 12’4″ | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.3 SCFM 38 l/min | 12/11 | 15″ x 16″ 38.1cm x 40.6cm | 21″ x 28″ 54cm x 71cm | 16″ x 22″ 41cm x 56cm | 12’4″ | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.3 SCFM 38 l/min | ||||||||||||||||||||||||||||||||

| 06/04 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 9’8 | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min | 06/05 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 9’8 | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min | 08/06 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 10’11” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min | 08/07 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 10’11” | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min | 10/08 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 12’3″ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min | 10/09 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 12’3″ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min | 12/10 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 13’6” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min | 12/11 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 13’6” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min | 14/12 | 16″ x 18″ 40.6cm x 45.7cm | 23″ x 33″ 58.4cm x 83.8cm | 16″ x 22″ 41cm x 56cm | 15’7″ | Boom | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min | ||||||||||||||||||||||||

| 06/04 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 10’5” | Boom | 1 ph 208/230v, 50/60 Hz, 13A 3 ph 208/230v, 50/60 Hz, 8A | 0.6 SCFM 17 l/min | 06/05 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 10’5” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.7 SCFM 21 l/min | 08/06 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 12′ | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min | 08/07 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 12′ | Boom | 1 ph 208/230v, 50/60 Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min | 10/08 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 13’8” | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min | 10/09 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 13’8” | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min | 12/10 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 15’3” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min | 12/11 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 15’3” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min | 14/12 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 16’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min | 16/14 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 18’4″ | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 27A | 1.9 SCFM 54 l/min | 18/16 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 19’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 30A | 2.0 SCFM 58 l/min | 20/18 | 20″ x 20″ 50.8cm x 50.8cm | 26″ x 36″ 66cm x 91.4cm | 16″ x 22″ 41cm x 56cm | 21’4” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 32A | 2.2 SCFM 63 l/min |

| 08/06 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 13’10” | Boom | 1 ph 208/230v, 50/60 Hz, 14A 3 ph 208/230v, 50/60 Hz, 9A | 0.9 SCFM 25 l/min | 08/07 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 13’10” | Boom | 1 ph 208/230v, 50/60Hz, 15A 3 ph 208/230v, 50/60 Hz, 10A | 1.1 SCFM 30 l/min | 10/08 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 15’ | Boom | 1 ph 208/230v, 50/60 Hz, 16A 3 ph 208/230v, 50/60 Hz, 11A | 1.2 SCFM 34 l/min | 10/09 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 15’ | Boom | 1 ph 208/230v, 50/60 Hz, 17A 3 ph 208/230v, 50/60 Hz, 12A | 1.3 SCFM 38 l/min | 12/10 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 16’6” | Boom | 1 ph 208/230v, 50/60 Hz, 18A 3 ph 208/230v, 50/60 Hz, 13A | 1.5 SCFM 42 l/min | 12/11 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 16’6” | Boom | 1 ph 208/230v, 50/60 Hz, 19A 3 ph 208/230v, 50/60 Hz, 14A | 1.6 SCFM 46 l/min | 14/12 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 18’ | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 16A | 1.8 SCFM 50 l/min | 16/14 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 19’6” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 27A | 1.9 SCFM 54 l/min | 18/16 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 20’10” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 30A | 2.0 SCFM 58 l/min | 20/18 | 20″ x 28″ 50.8cm x 71cm | 26″ x 43″ 66cm x 109.2cm | 16″ x 22″ 41cm x 56cm | 22’8” | Stationary Arm | 3 ph 208/230v, 50/60 Hz, 32A | 2.2 SCFM 63 l/min |

PREMIUM SERVICE THAT WILL EXCEED YOUR EXPECTATIONS

Customer Service and Support are a way of life at Anatol Equipment. We strive to improve our service to keep your equipment running like the day you had it installed. This is our commitment to every customer. Two-year limited warranty.

Anatol Support Contacts

We’re Here to Assist You!

Our support team is just a call away. Whether you have a question or need immediate assistance, we’re ready to help you keep your operations running smoothly. 847-582-1825

Get in TouchWarranty Registration

Secure Your Investment

Register your Anatol machine to activate your warranty and enjoy peace of mind. Complete the simple form for each piece of equipment, and rest easy knowing your machine is covered. (Two years for most equipment, three years for the VOLT automatic press.)

Regsiter NowQuestions & Answers

Find Answers Quickly

Have questions? We’ve got answers. Explore our comprehensive FAQ section where you’ll find solutions to the most common inquiries from our customers.

View FAQsFAQ

What makes the VECTOR Series different from other automatic screen printing machines?

The VECTOR Series stands out due to its unique combination of electric and pneumatic technology, offering reduced air consumption, advanced control features, and unparalleled precision. It also provides a wide range of print areas and is available in multiple configurations, making it one of the most versatile presses on the market.

Can the VECTOR Series handle large print runs efficiently?

Yes, the VECTOR Series is designed for high efficiency, making it ideal for large print runs. Its advanced servo-driven indexer ensures smooth, high-speed operation, and its user-friendly controls allow for quick setup and consistent results across multiple runs.

Is the VECTOR Series compatible with other Anatol equipment?

Absolutely. The VECTOR Series is compatible with Anatol’s ARME pre-registration system, specialty pallets, flash cure units and various other accessories like the Big Forge and Mobile Forge in-line heat presses, allowing you to create a fully integrated printing setup tailored to your needs.

What kind of maintenance does the VECTOR Series require?

The VECTOR Series is designed with fewer pneumatic components, reducing maintenance needs. The pallet carousel, indexer and print heads require simple lubrication to keep the machine running smoothly, ensuring long-term reliability and performance. Receive routine maintenance reminders on the touchscreen of the press so you know when it’s time to perform a maintenance item.

How does the VECTOR Series improve print quality?

The VECTOR Series enhances print quality through precise registration, consistent pressure, and controlled off-contact settings. Its servo-driven print heads and adjustable settings ensure that every print is accurate, vibrant, and of the highest quality.