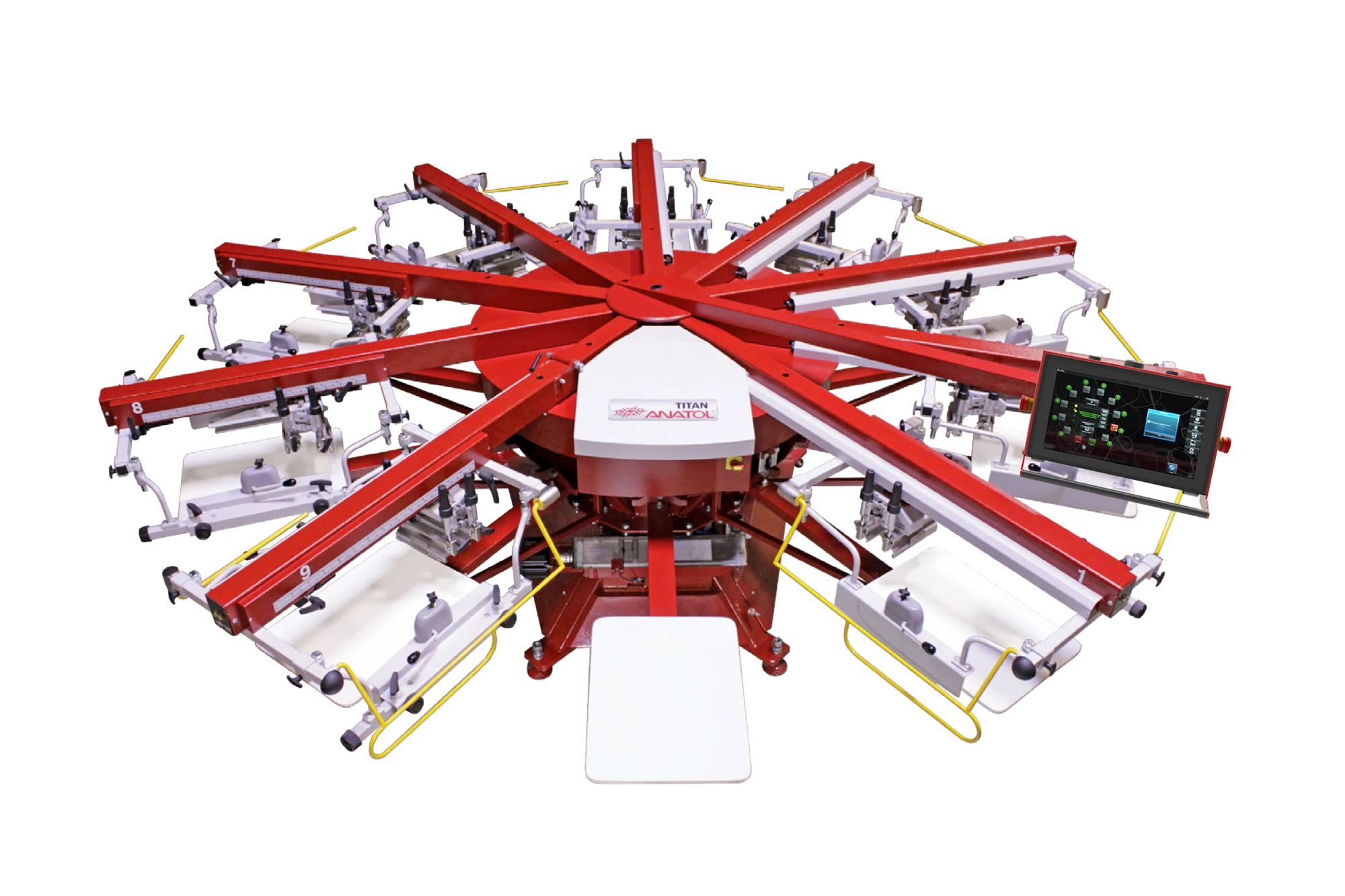

Titan

The TITAN by Anatol is an economical and versatile machine that makes it an ideal starter automatic. This automatic screen printing press is engineered for low air consumption and energy efficiency, putting it at the top of the class when it comes to entry-level automatic presses.

TITAN packs advanced technology and features you’d typically expect to find only on top-of-the-line equipment, into a budget-friendly package. Available in configurations from 4 up to 11 colors, there is a TITAN to fit your screen printing needs.

Description

Standard features

Specifications

Support

The TITAN automatic screen printing press by Anatol: The Perfect First Step into the World of Automatic Printing

The TITAN series is designed as an accessible entry point into automatic screen printing. It’s powered by our exclusive Aries 2 operating system with clear and simple functions and minimal dropdown menus, making it easy to learn and quick to navigate. The Titan is available in configurations from 4 colors up to 11 colors, with a diameter starting at just 9’4” to fit shops that are tight on space. And because TITAN consumes minimal air, you don’t need a large, noisy and expensive compressor to power it.

Standout Feature: Heads Up for Maximum Versatility

A standout feature that sets the TITAN (and other Anatol automatic presses) apart from the competition is its Head Up feature, found on machines with an odd number of print heads. The last print head is on a hinge, so you can raise the head out of the way when you don’t need it for printing, creating dedicated loading and unloading stations so multiple operators can get jobs done faster than one person.

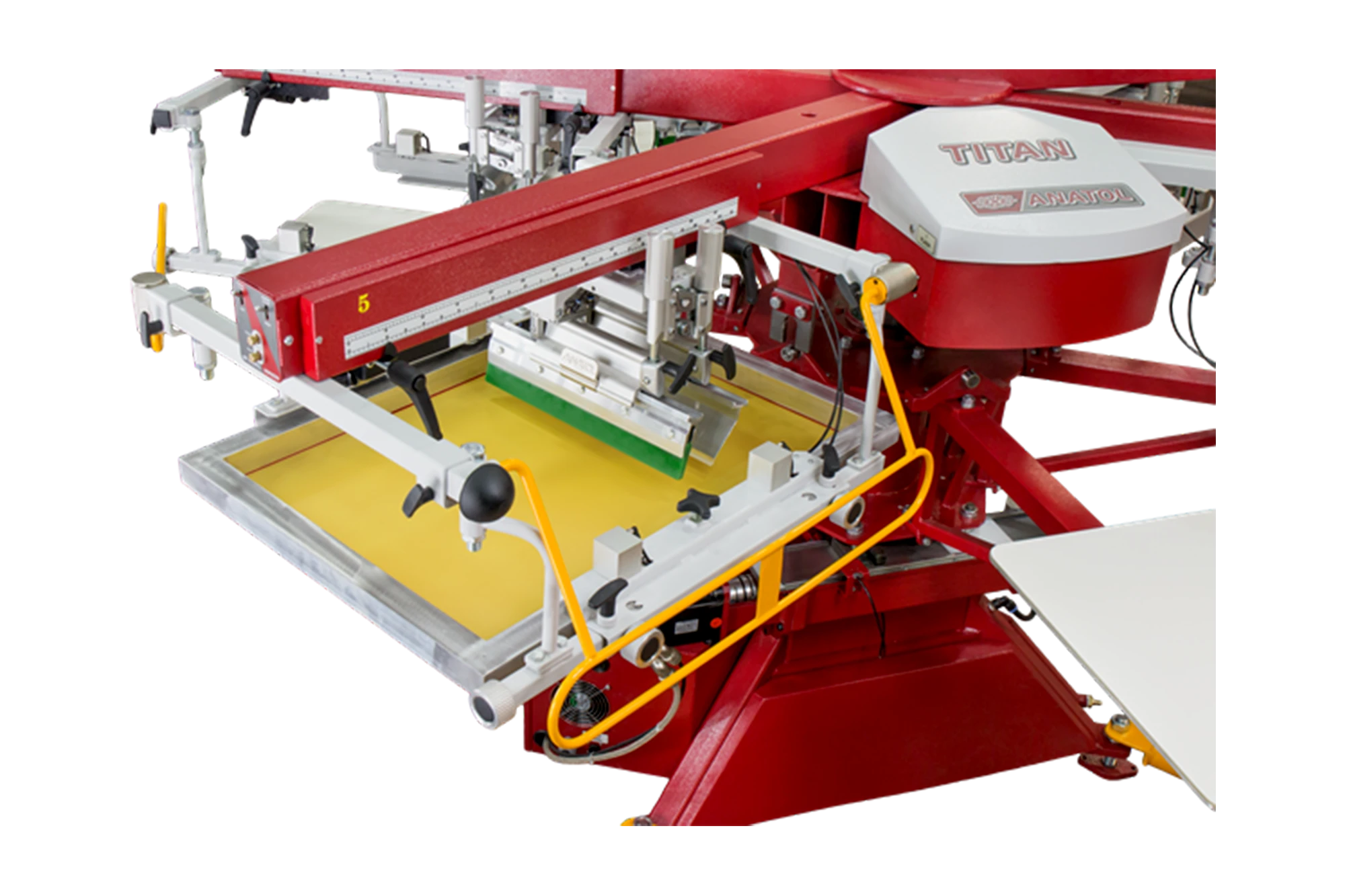

Precision Registration

Like its big brothers, the VECTOR and VOLT, the TITAN features a true three-point micro-registration system that offers smooth, precise adjustments when lining up multicolor print jobs. The TITAN is also compatible with Anatol’s ARME pre-registration system, to help you register multicolor prints quickly and accurately.

User-Friendly Control Interface

The TITAN’s control interface features the Aries 2 OS, the same intuitive operating system found on Anatol’s top-of-the-line VOLT presses. The 15’’ touchscreen provides one-touch access to all job settings, making setups fast and easy, while the rotating boom arm allows for convenient access from any print head.

Hybrid Pneumatic/Electric Technology

TITAN presses are available in three different “trim levels”:

AAA = air pallet lift/air indexing/air print heads

ASA = air pallet lift/servo indexing/air print heads

ASE = air pallet lift/servo indexing/AC-electric print heads

The TITAN series ranges from our most budget-friendly option, the AAA, to the more advanced and capable ASA and ASE models with expanded features, greater efficiency and reliability.

Heads Up Feature

On TITAN automatic screen printing presses with an odd number of print heads, the Heads Up Feature allows the last head to be lifted on a hinge, creating dedicated loading and unloading stations. This feature effectively turns a 10-station/9-color machine into a 10-station/8-color machine, increasing workflow efficiency by allowing two operators to work simultaneously. This innovation enables faster production speeds and greater flexibility in your screen printing operations.

Registration

The TITAN’s registration system offers true three-point micro-registration, providing precise adjustments in front-back, left-right, and rotational movements. Compatible with Anatol’s ARME pre-registration system as well as other common pre-registration systems, this feature ensures that every print is aligned perfectly, reducing setup time and increasing print accuracy across all screen printing jobs.

Control Interface

Powered by the Aries 2 OS, the TITAN Series includes a 15’’ touchscreen interface that offers intuitive, one-touch access to all job settings and machine functions. The rotating boom arm allows easy access to the touchscreen from any print head, simplifying setup and adjustments. Quick access to the operator’s manual and automatic software updates via Wi-Fi ensure that your screen printing machine is always operating at peak performance.

Functions

The TITAN automatic t-shirt printing machine allows you to save all parameters of stored jobs, including indexing speed, number of strokes, flash cure time, and temperature. The smart flash feature lets you set the pallet preheat temperature, ensuring consistent and high-quality prints every time. These advanced functions streamline your workflow and minimize downtime.

Central Off-Contact

With a gauged click mechanism that allows for precise adjustments up to 2/5 inch, the TITAN offers 68 off-contact settings—well above industry standards. This provides maximum control when printing on a variety of substrates or using specialty inks. The TITAN’s central off-contact system is the most advanced mechanical system available in any screen printing press today.

Print Heads

The TITAN Series offers pneumatically-driven print heads in AAA and ASA models, or A/C electric print heads in ASE models. Features include independent flood/print speed control, single-handed squeegee/flood bar adjustments with a range of 0°-30°, front and rear stroke adjustments, and gauged squeegee/flood bar knobs for easy depth adjustments. Side screen clamps accommodate a wide range of screen sizes, making this commercial screen printer versatile for any job.

Safety System

The TITAN’s safety system includes patented safety bars located between each print head and on each side of the load and unload stations. These safety measures ensure that operators remain protected during press setup and operation, making the TITAN one of the safest silk screen printing presses available.

Skip Shirt & Smash Button

Prevent costly errors and wasted materials with the TITAN’s Skip Shirt function, which stops the press from printing on empty pallets. The Smash Button feature allows you to easily skip improperly loaded shirts, reducing the chances of misprints and ensuring consistent quality across all t-shirt printing jobs.

Indexing System

The TITAN’s indexing system features a servo-driven indexer for models ASA and ASE, allowing for clockwise, counterclockwise, and half-indexing. The AAA models include a pneumatic indexer with clockwise direction. Step-Back and Multi Step-Back programs are available on servo indexer models and on pneumatic models with 6 stations/5 colors or fewer, offering increased flexibility in print sequencing and efficiency.

Pallet System

The TITAN’s pallet system features slide-style pallets that allow for precise adjustments in print location. The tool-free locking mechanism and four-point pallet leveling system ensure accuracy and consistency. Standard 16’’x22’’ solid aluminum, low-profile rubber-coated pallets are included, with a wide range of specialty and custom pallets available separately. A laser alignment system is included for quick and easy pallet positioning and apparel substrate alignment, ensuring optimal results for every print.

Options

The TITAN Series offers a range of options to enhance your screen printing machine. These include quartz flash cure units, a quick-release pallet system, a foot pedal to control indexing, individual print head controls, and special sizing options for doorways as small as 28’’. These customizable options ensure that the TITAN can be tailored to meet the specific needs of your screen printing operation.

Titan S

Titan M

AAA

ASA

ASE

| Model | Air Requirement @ 90 PSI | Power Requirement | Diameter | Air Requirement @ 90 PSI | Power Requirement | Diameter | Air Requirement @ 90 PSI | Power Requirement | Diameter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6/4 S | 9.7 SCFM (274 l/min) | 1ph, 115 VAC, 2A | 9’4” | 7.9 SCFM (223 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 9’4” | 2.0 SCFM (58 l/min) | 1ph, 208 VAC, 10A 3ph, 208 VAC, 6A | 9’4” | 6/5 S | 11.3 SCFM (319 l/min) | 1ph, 115 VAC, 2A | 9’4” | 9.5 SCFM (268 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 9’4” | 2.2 SCFM (62 l/min) | 1ph, 208 VAC, 11A 3ph, 208 VAC, 6A | 9’4” | 8/6 S | 12.9 SCFM (365 l/min) | 1ph, 115 VAC, 2A | 10’2” | 11.1 SCFM (314 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 10’2” | 2.4 SCFM (68 l/min) | 1ph, 208 VAC, 11A 3ph, 208 VAC, 7A | 10’2” | 8/7 S | 14.5 SCFM (410 l/min) | 1ph, 115 VAC, 2A | 10’2” | 12.7 SCFM (359 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 10’2” | 2.5 SCFM (72 l/min) | 1ph, 208 VAC, 12A 3ph, 208 VAC, 7A | 10’2” | 10/8 S | - | - | - | 14.3 SCFM (404 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 11’1” | 2.7 SCFM (76 l/min) | 1ph, 208 VAC, 14A 3ph, 208 VAC, 9A | 11’3” | 10/9 S | - | - | - | 15.9 SCFM (449 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 11’1” | 2.8 SCFM (80 l/min) | 1ph, 208 VAC, 14A 3ph, 208 VAC, 9A | 11’3” | 12/10 S | - | - | - | 17.5 SCFM (495 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 12’3” | 3.0 SCFM (85 l/min) | 1ph, 208 VAC, 16A 3ph, 208 VAC, 11A | 12’3” | 12/11 S | - | - | - | 19.1 SCFM (540 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 12’3” | 3.1 SCFM (87 l/min) | 1ph, 208 VAC, 16A 3ph, 208 VAC, 11A | 12’3” |

| 6/4 M | 9.8 SCFM (278 l/min) | 1ph, 115 VAC, 2A | 9’8” | 8.1 SCFM (223 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 9’8” | 2.0 SCFM (58 l/min) | 1ph, 208 VAC, 10A 3ph, 208 VAC, 6A | 9’8” | 6/5 M | 11.4 SCFM (323 l/min) | 1ph, 115 VAC, 2A | 9’8” | 9.6 SCFM (272 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 9’8” | 2.2 SCFM (62 l/min) | 1ph, 208 VAC, 11A 3ph, 208 VAC, 6A | 9’8” | 8/6 M | 13.0 SCFM (369 l/min) | 1ph, 115 VAC, 2A | 10’11” | 11.2 SCFM (318 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 10’11” | 2.4 SCFM (68 l/min) | 1ph, 208 VAC, 11A 3ph, 208 VAC, 7A | 10’11” | 8/7 M | 14.6 SCFM (414 l/min) | 1ph, 115 VAC, 2A | 10’11” | 12.9 SCFM (364 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 10’11” | 2.5 SCFM (72 l/min) | 1ph, 208 VAC, 12A 3ph, 208 VAC, 7A | 10’11” | 10/8 M | - | - | - | 14.4 SCFM (408 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 12’3″ | 2.7 SCFM (76 l/min) | 1ph, 208 VAC, 14A 3ph, 208 VAC, 9A | 12’5” | 10/9 M | - | - | - | 16.0 SCFM (454 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 12’3″ | 2.8 SCFM (80 l/min) | 1ph, 208 VAC, 14A 3ph, 208 VAC, 9A | 12’5” | 12/10 M | - | - | - | 17.6 SCFM (498 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 13’6” | 3.0 SCFM (85 l/min) | 1ph, 208 VAC, 16A 3ph, 208 VAC, 11A | 13’6” | 12/11 M | - | - | - | 19.2 SCFM (545 l/min) | 1ph, 208 VAC, 6A 3ph, 208 VAC, 4A | 13’6” | 3.1 SCFM (87 l/min) | 1ph, 208 VAC, 16A 3ph, 208 VAC, 11A | 13’6” |

EXCEPTIONAL SERVICE AND SUPPORT THAT YOU CAN RELY ON

At Anatol Equipment, customer satisfaction is at the core of everything we do. Our dedicated support team is here to ensure that your equipment continues to operate at peak performance from the day it’s installed. We’re committed to providing top-notch service to every customer, backed by a two-year limited warranty—and a three-year warranty on the VOLT automatic press.

Anatol Support Contacts

We’re Here to Assist You!

Our support team is just a call away. Whether you have a question or need immediate assistance, we’re ready to help you keep your operations running smoothly. 847-582-1825

Get in TouchWarranty Registration

Secure Your Investment

Register your Anatol machine to activate your warranty and enjoy peace of mind. Complete the simple form for each piece of equipment, and rest easy knowing your machine is covered. (Two years for most equipment, three years for the VOLT automatic press.)

Regsiter NowQuestions & Answers

Find Answers Quickly

Have questions? We’ve got answers. Explore our comprehensive FAQ section where you’ll find solutions to the most common inquiries from our customers.

View FAQsFAQ

1. What makes the TITAN Series different from other automatic screen printing presses?

The TITAN series is designed to consume minimal air versus competing machines. By reducing pneumatic components down to one or two air cylinders per print head (depending on the model), the TITAN has fewer moving parts to wear out and fail over time, reducing maintenance and downtime. Competing presses can use as many as 10 to 12 air cylinders per print head, which is a lot that can go wrong. TITAN is built for reliability and energy efficiency.

2. How many configurations are available for the TITAN Series?

The TITAN series is available in a wide variety of configurations, from all-air (AAA) models to hybrid pneumatic/electric machines (ASA and ASE). TITANs range in size from 4 colors up to 11 colors, and maximum print areas of 15” x 16” or 16” x 18”. This flexibility allows you to choose the perfect setup for your production needs and your budget.

3. Is the TITAN Series suitable for small businesses?

Yes, the TITAN Series is ideal for small businesses looking for a reliable and efficient automatic screen printing press. Its advanced features and customizable options make it easy to scale your operations while maintaining high-quality output.

4. What kind of print heads does the TITAN Series use?

The TITAN Series offers pneumatically-driven print heads in AAA and ASA models, and A/C electric print heads in ASE models. Each type provides independent flood/print speed control, ensuring smooth and precise printing.

5. Can I use the TITAN Series for printing on different substrates?

Absolutely. The TITAN’s advanced central off-contact system with 68 settings allows for precise adjustments, making it easy to print on various substrates, including t-shirts, hoodies, and specialty materials.