Rapid

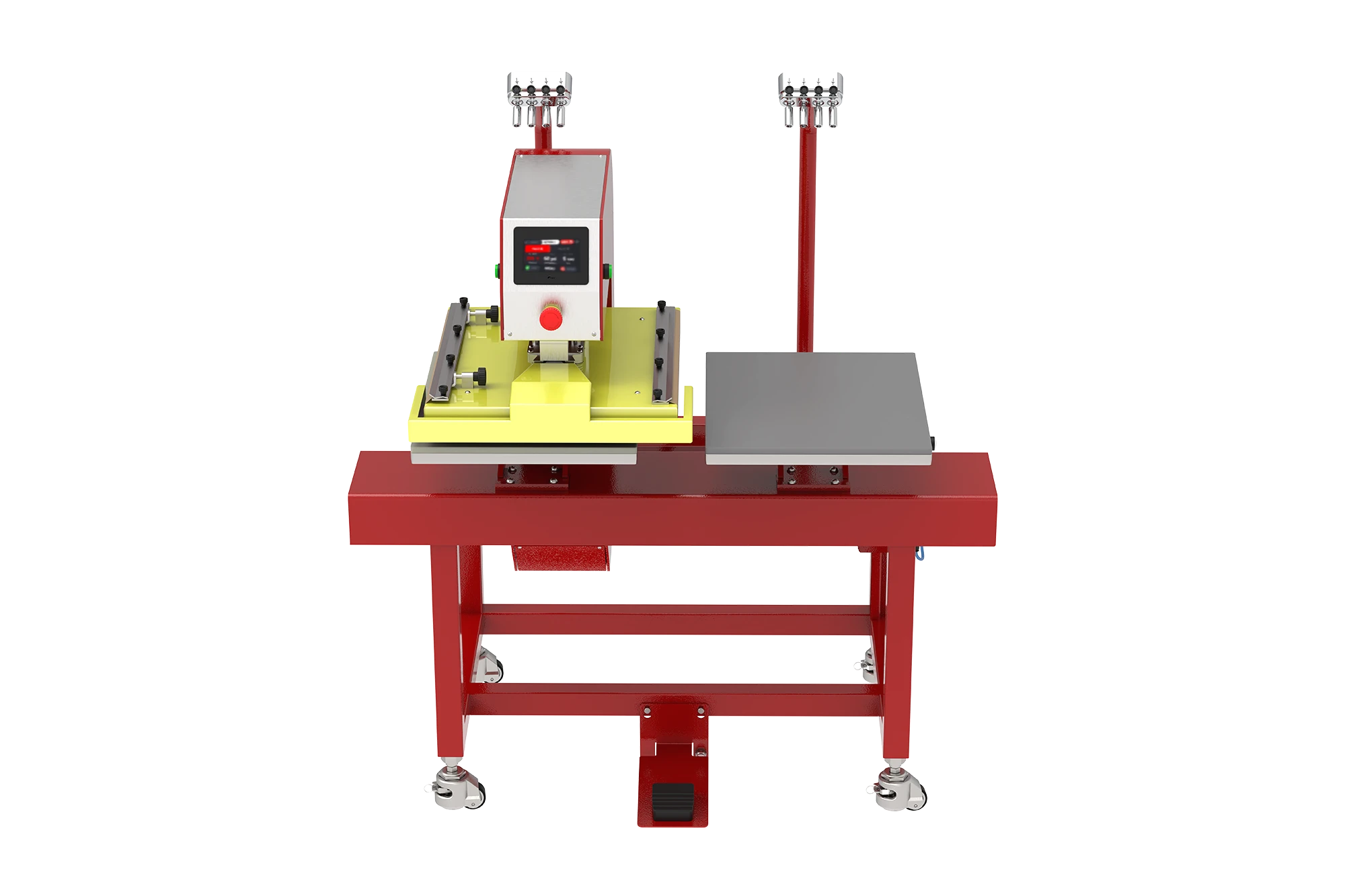

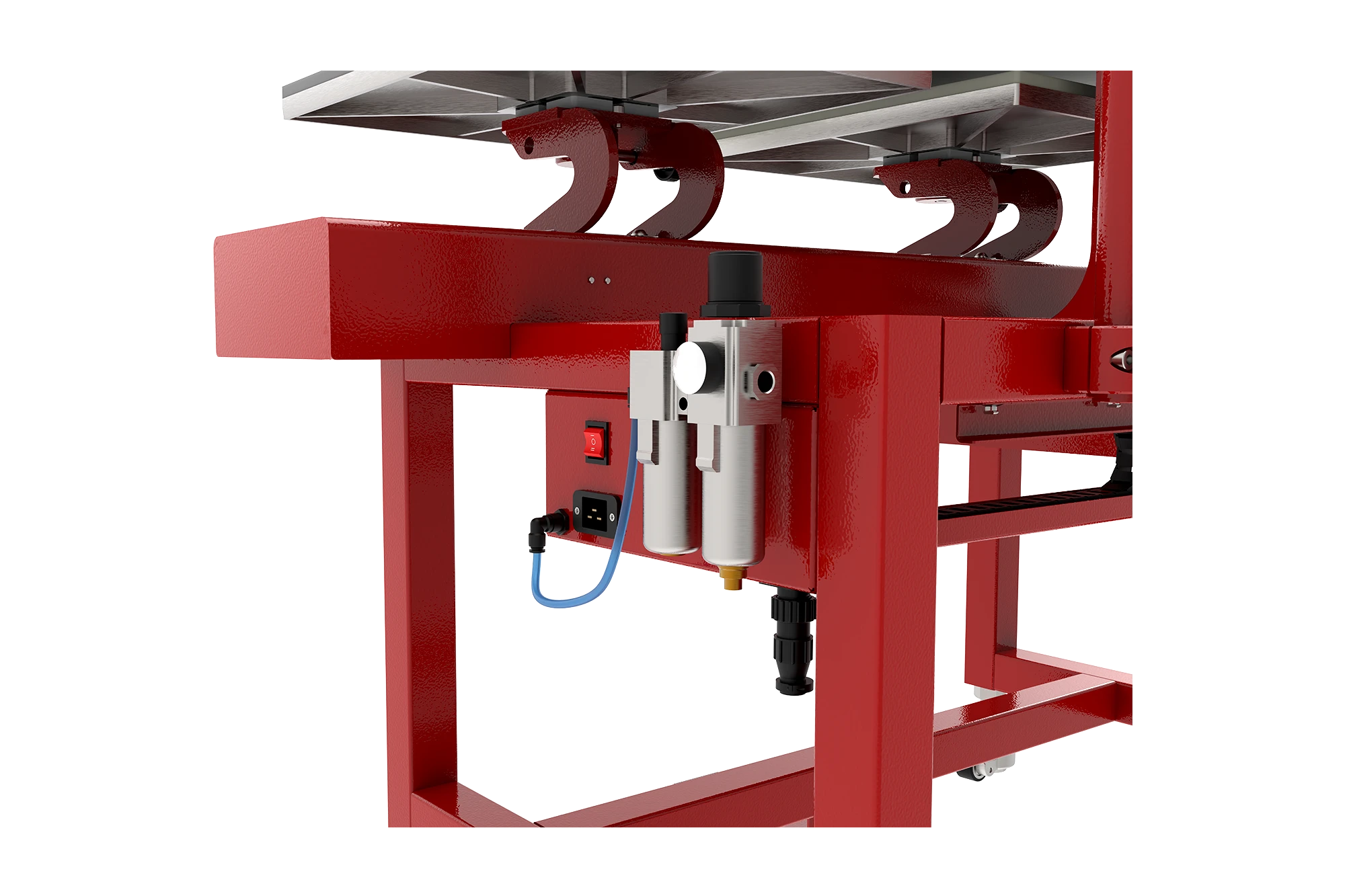

The Rapid Transfer System (RTS) by Anatol is an industrial-grade heat press machine designed for fast and efficient application of heat-applied graphics, special effects, and more. With a maximum pressure of 120 PSI and fully pneumatic operation, the RTS ensures consistent, high-quality results. The user-friendly touchscreen interface allows you to easily control temperature, pressure, and time, with the ability to save and recall job settings for faster setups. Perfect for enhancing production output and print quality, the RTS is ideal for both DTG and DTF printing processes.

Description

Standard features

Specifications

Support

Revolutionizing Heat Transfer Printing: The Rapid Transfer System

Introducing the RTS by Anatol

The Rapid Transfer System (RTS) by Anatol is designed to revolutionize your heat transfer printing process. It combines industrial strength with user-friendly operation. This automatic heat press machine, with its two stations, applies transfers, foil, and other heat-applied decorations with precision and ease. It allows significant production increases with minimal effort compared to manual presses.

Durable Construction for Longevity

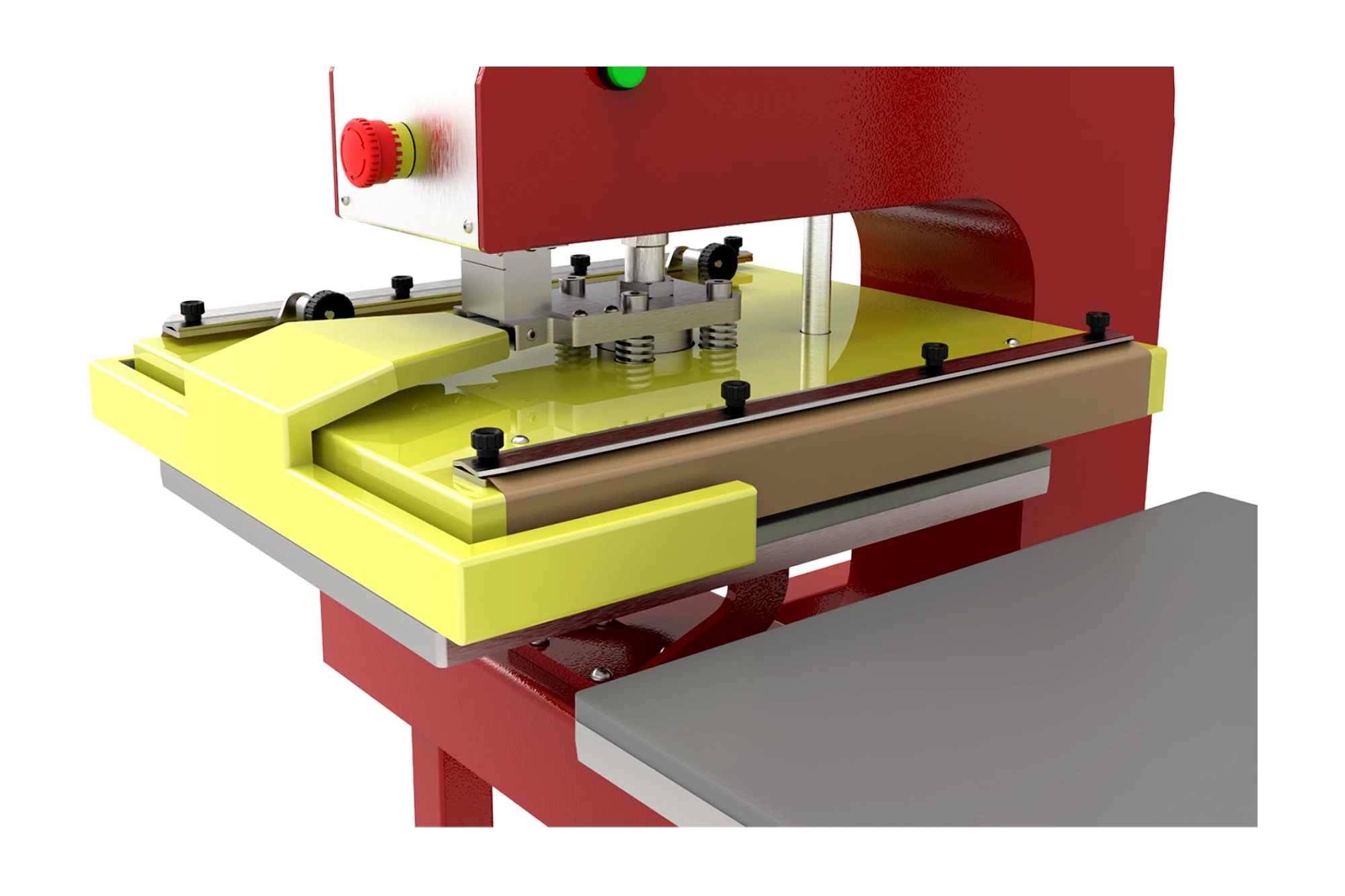

Constructed with heavy-duty steel, the RTS is built to withstand demanding production environments, ensuring years of reliable service. It comes standard with two 16” x 20” pallets, with specialty pallets available for specific applications. The non-stick PTFE-covered heating surface ensures even heat distribution, guaranteeing consistent, high-quality results with every print.

Advanced Control Features

Controlled via a 4.3” full-color touchscreen, the RTS allows easy programming and adjustment of temperature, pressure, and time settings. This heat press offers manual, semi-automatic, and automatic operation modes, letting you adjust your production pace as needed. For added efficiency, the RTS enables you to save and recall job settings, reducing setup time and ensuring consistent output.

Precision and Efficiency

The built-in four-head laser alignment system ensures precise placement of garments and prints, minimizing misprints and waste. Combined with foot pedal control, this system significantly enhances the efficiency of your operation. The RTS is an essential tool for any business involved in custom screen print transfers, silk screen transfers, or heat transfer printing, making it a valuable addition to your production line.

Conclusion: A Must-Have for Enhanced Productivity

With its robust design and advanced features, the RTS by Anatol stands out as a must-have for businesses looking to improve their heat transfer printing processes. Its ability to boost production, paired with its ease of use and precise control, makes the RTS an invaluable investment for enhancing productivity and quality in any print shop

FAQ

1. What is the maximum pressure the Rapid Transfer System can apply?

2. Can the Rapid Transfer System be used with custom screen print transfers?

3. How do I control the temperature, pressure, and time settings on the RTS?

4. Is the Rapid Transfer System suitable for DTG and DTF printing?

5. What sizes of pallets come with the Rapid Transfer System?

6. How does the laser alignment system work on the Rapid Transfer System?

7. Can the Rapid Transfer System operate in different modes?

8. What are the air and electrical requirements for the Rapid Transfer System?