Scaling up your screen printing business is an exciting but also challenging task. As your business grows, so do your equipment needs. Having the right equipment and accessories is critical to maintaining production efficiency, quality, and profitability. Anatol, one of the most respected brands in the screen printing industry, offers advanced solutions to help you scale efficiently. Anatol equipment provides you with the tools you need to succeed.

In this article, we’ll look at how to scale your screen printing business with Anatol screen printing machines. We will highlight the differences between manual and automatic presses. We will also provide a roadmap for businesses looking to expand their production capabilities.

Why Scaling Your Screen Printing Business Matters

Growth is a natural part of any successful business. However, to scale efficiently, it’s essential to have the right infrastructure in place. The demands of larger orders and quicker turnarounds can strain your existing setup, leading to issues such as longer production times, inconsistent print quality, and unnecessary operational costs.

To prepare for growth, it’s critical to invest in high-quality screen printing equipment that can handle increased workloads without sacrificing quality. Whether you need to automate parts of your process, improve drying times, or scale up your ink mixing and curing capacity, Anatol offers solutions for every stage of growth.

The Importance of Automation: Manual vs. Automatic Screen Printing Presses

As your business grows, one of the first decisions you’ll need to make is whether to continue using manual screen printing presses or invest in automatic screen printing machines. Let’s compare the two:

Manual Screen Printing Presses

Anatol’s Tornado and Lighting hand presses are ideal for small businesses or startups. They are affordable, durable, and allow you to maintain a hands-on approach to each print. However, as order volumes increase, manual printing can be labor-intensive and time-consuming. This limits your ability to take on larger, high-volume orders.

- Pros:

- Lower initial cost

- Greater control over the printing process

- Ideal for small-scale or custom jobs

- Cons:

- Slower production times

- Requires more manual labor

- Difficult to scale for high-volume orders

Automatic Screen Printing Presses

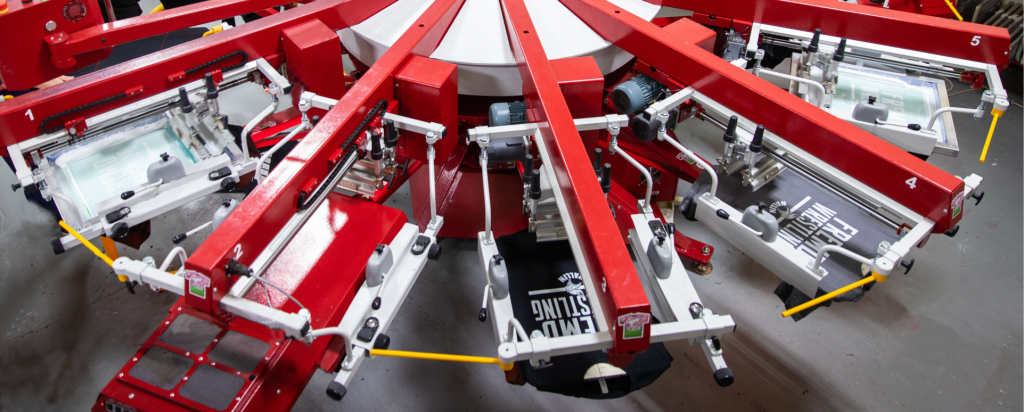

For growing companies, switching to automatic screen printing machines can be a game changer. And the VOLT Electric Press or Vector from Anatol will provide reliability and cost-effectiveness. These machines allow you to print much faster while maintaining consistent quality. Automatic presses are designed to efficiently fulfill large volumes of orders in production. This makes them ideal for businesses looking to scale up.

- Pros:

- High-speed production

- Consistent print quality

- Reduces labor costs and manual effort

- Ideal for large orders

- Cons:

- Higher initial investment

- Requires more space and technical knowledge

Expert Tip: If your business is moving towards higher-volume orders or handling more complex multi-color designs, investing in an automatic screen printer machine can significantly increase your capacity while reducing production time.

Essential Anatol Equipment for Scaling Your Business

As your orders grow, so does the need for more efficient, higher-capacity equipment. Below are some essential Anatol screen printing machines and accessories to consider for scaling your business:

1. Automatic Screen Printing Machines

- VOLT Electric Automatic Press: Known for its reliability and efficiency, the VOLT is one of the only industrial-grade all-electric presses available, offering faster setup times and lower operational costs due to the lack of pneumatic components.

- Vector Automatic Screen Printing Press: Designed for high-volume production, the Vector is equipped with features like touchscreen controls and servo motors to enhance speed and precision.

2. Conveyor Dryers

To handle larger orders, you’ll need an efficient drying solution that keeps up with your production speed. Anatol’s Ultra Forced Air Electric Conveyor Dryer is perfect for medium to large shops, providing uniform curing for garments of all sizes. For even larger operations, the Vulcan Gas Conveyor Dryer offers the highest efficiency for industrial-level drying.

3. Flash Cure Units

A reliable flash cure unit is essential for drying ink between layers when printing multi-color designs. Anatol’s Rapid Wave Flash Cure Unit uses advanced technology to cure prints quickly and evenly, improving overall production time.

4. Pre-Press Equipment

Efficient pre-press processes are vital for scaling your business. The Aurora UV LED Exposure Unit from Anatol speeds up screen exposure, allowing you to prepare screens faster and more accurately, reducing setup times and ensuring consistent print quality.

Creating a Scalable Workflow: Tips for Effective Growth

Growth requires not only investment in new machines, but also optimization of the workflow. Here are a few tips to help ensure that your screen printing business scales smoothly:

1. Automate Where Possible

Automating key processes, such as screen preparation, ink mixing, and curing, will not only speed up production but also reduce errors and labor costs. Consider adding an automatic screen printing machine and a screen print dryer to your setup.

2. Focus on Quality Control

As you scale, maintaining consistent quality becomes more challenging. Equipment like Anatol’s Cube Drying Cabinet ensures that your screens are dried evenly, preventing warping and ensuring long-lasting, high-quality prints.

3. Invest in Training

Scaling your business means managing a larger team and more complex operations. Ensure that your staff is well-trained in operating new screen printing machines and accessories to avoid costly mistakes and downtime.

4. Monitor Energy Efficiency

Larger operations consume more energy, which can significantly increase operational costs. Anatol’s VOLT Electric Press and energy-efficient conveyor dryers are designed to minimize energy usage while maximizing output.

Frequently Asked Questions (FAQs)

1. What is the best equipment for a growing screen printing business?

For businesses looking to scale, an automatic screen printing machine like Anatol’s VOLT Electric Press or Vector is a great investment. These machines handle large-volume orders quickly and consistently.

2. How do I know when to switch from manual to automatic presses?

If you’re experiencing bottlenecks in production or need to fulfill large orders with faster turnarounds, it may be time to invest in an automatic screen printer machine. This will improve your efficiency and reduce labor costs.

3. How can I ensure my business stays efficient as it grows?

Investing in energy-efficient equipment like Anatol’s conveyor dryers and pre-press machines will help keep your operational costs down while maintaining high production quality.

Final Thoughts: Preparing for Future Growth with Anatol

Scaling up your screen printing business is an exciting opportunity. With the right equipment from Anatol, you can ensure your growth is both profitable and sustainable. Whether you’re looking to upgrade to an automatic screen printing machine, optimize your curing process with a heat press, or improve your workflow with prepress equipment, Anatol has the right solution for every business.

Investing in high-quality and reliable equipment is the key to long-term success. When expanding production, do not forget to prioritize efficiency. Maintain high quality standards and train your staff to work with new technologies. With screen printing equipment from Anatol, your business will be ready for whatever the future holds.